Workshop

Testing

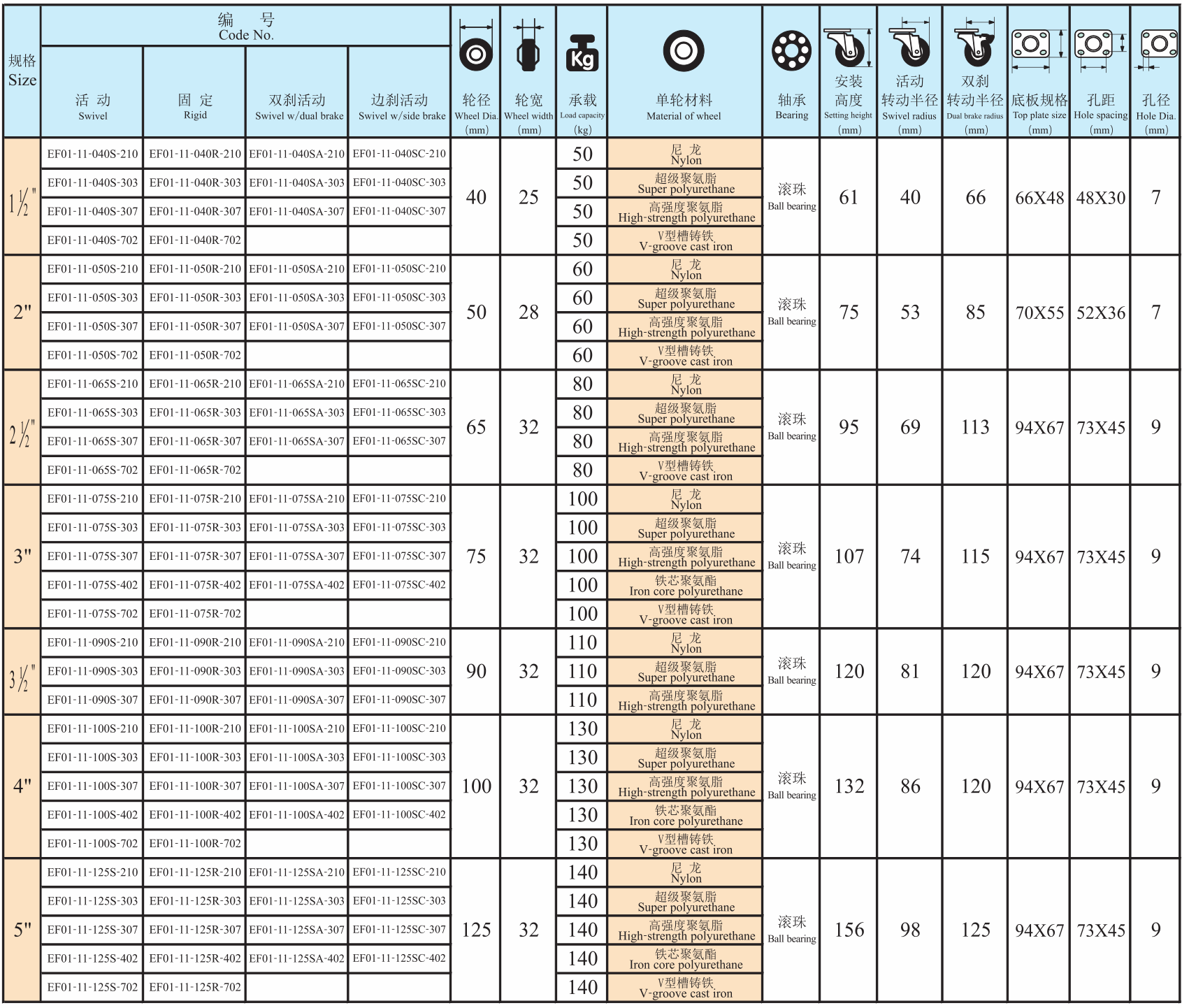

Installation height: refers to the vertical distance from the ground to the installation position of the equipment, and the installation height of the casters refers to the maximum vertical distance from the bottom of the caster and the edge of the wheel. Bracket steering center distance: refers to the horizontal distance from the vertical line of the center rivet to the center of the wheel core. Turning radius: refers to the horizontal distance from the vertical line of the center rivet to the outer edge of the tire. The proper spacing enables the casters to make a 360-degree turn. Whether the turning radius is reasonable or not directly affects the service life of the casters. Driving load: The load-bearing capacity of casters when they are moving is also called dynamic load. The dynamic load of casters differs due to different test methods in the factory and different materials of the wheels. The key lies in whether the structure and quality of the bracket can resist impact and Shock. Impact load: The instantaneous load-bearing capacity of the caster when the equipment is impacted or shaken by the load. Static load Static load Static load Static load: The weight that a caster can bear in a static state. The static load should generally be 5-6 times the exercise load (dynamic load), and the static load should be at least 2 times the impact load. Steering: Hard, narrow wheels are easier to steer than soft, wide wheels. The turning radius is an important parameter for wheel rotation. Too short a turning radius will increase the difficulty of steering, and too large a turning radius will cause the wheel to shake and shorten the lifespan. Driving flexibility: The factors that affect the driving flexibility of the casters include the structure of the bracket and the selection of bracket steel, the size of the wheel, the type of the wheel, the bearing, etc. The larger the wheel, the better the driving flexibility, and it is hard and narrow on a stable ground. Wheels are less labor-intensive than flat-edged soft wheels, but on uneven ground, soft wheels are less labor-intensive, but on uneven ground, soft wheels can better protect the equipment and absorb shock!

Installation height: refers to the vertical distance from the ground to the installation position of the equipment, and the installation height of the casters refers to the maximum vertical distance from the bottom of the caster and the edge of the wheel. Bracket steering center distance: refers to the horizontal distance from the vertical line of the center rivet to the center of the wheel core. Turning radius: refers to the horizontal distance from the vertical line of the center rivet to the outer edge of the tire. The proper spacing enables the casters to make a 360-degree turn. Whether the turning radius is reasonable or not directly affects the service life of the casters. Driving load: The load-bearing capacity of casters when they are moving is also called dynamic load. The dynamic load of casters differs due to different test methods in the factory and different materials of the wheels. The key lies in whether the structure and quality of the bracket can resist impact and Shock. Impact load: The instantaneous load-bearing capacity of the caster when the equipment is impacted or shaken by the load. Static load Static load Static load Static load: The weight that a caster can bear in a static state. The static load should generally be 5-6 times the exercise load (dynamic load), and the static load should be at least 2 times the impact load. Steering: Hard, narrow wheels are easier to steer than soft, wide wheels. The turning radius is an important parameter for wheel rotation. Too short a turning radius will increase the difficulty of steering, and too large a turning radius will cause the wheel to shake and shorten the lifespan. Driving flexibility: The factors that affect the driving flexibility of the casters include the structure of the bracket and the selection of bracket steel, the size of the wheel, the type of the wheel, the bearing, etc. The larger the wheel, the better the driving flexibility, and it is hard and narrow on a stable ground. Wheels are less labor-intensive than flat-edged soft wheels, but on uneven ground, soft wheels are less labor-intensive, but on uneven ground, soft wheels can better protect the equipment and absorb shock!